This website uses cookies to ensure you get the best experience

OK

Understanding and co-creating bioeconomic futures. You can find out here the ‘why, what and how’!

Past Events

The past events and further information can be found on the project pages.

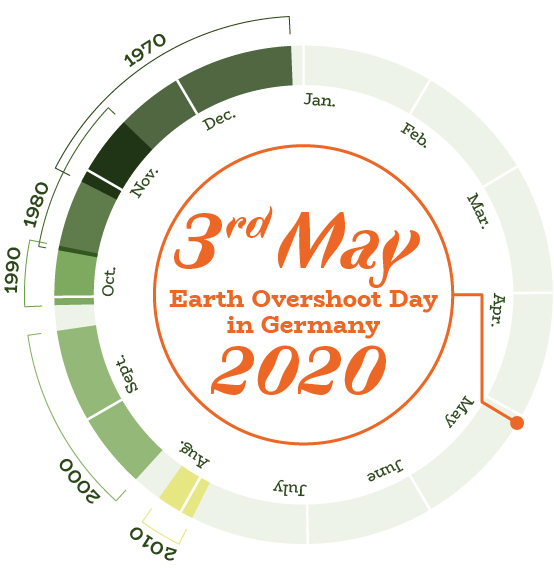

Enormous progress has been made in the fight against poverty and many people are better off today than ever before. Nevertheless, challenges remain: the climate is changing, biodiversity is declining, resources are becoming scarce. The excessive consumption of resources is illustrated by the Earth Overshoot Day. This is the day on which all the natural resources that the earth can regenerate and provide in a sustainable manner within one year are used up. At the same time, the demand for resources is actually increasing. According to United Nations estimates, the world population will have grown to 9.6 billion people by 2050. Increasing per capita incomes in the developing and emerging countries will cause consumption to rise further and, as a result, also the consumption of resources.

Global challenges

The transition towards bioeconomy is one of the most important requirements in the 21st century.

A threat to the prosperity of society

The prosperity achieved in the course of industrializsation over the past 200 years is increasingly pushing against planetary boundaries. Oil resources are limited, and even more critical is the fact that emissions from the use of fossil fuels are heating up the earth's atmosphere, and leading to global climate change, with serious consequences for both humans and nature. The diversity in the animal and plant worlds is decreasing. The current rate of global species extinction is dozens to hundreds times higher than the average of the last 10 million years. In order to ensure prosperity within planetary boundaries, societies' fundamental transformation is therefore required.

International Earth Overshoot Day

by decades (1970-2020)

by decades (1970-2020)

Planetary boundaries

Crossing planetary boundaries jeopardizzes future prosperity.

Crossing planetary boundaries jeopardizzes future prosperity.

The bioeconomy can and must help to drive this change. As an alternative to the prevailing economic system, which is based on the intensive use of fossil resources, the bioeconomy is instead relying on the use of renewable resources such as plants, animals and microorganisms. Due to this changed focus on resources, the bioeconomy is seen as a possible way to develop sustainable societies. Following the idea of the bioeconomy, the current economic system needs to be restructured and put on a sustainable foundation.

Bioeconomy as a sustainable foundation for future societies

1.5 degree target

Under the Paris Climate Convention, 195 states have committed themselves under international law to reduce the increase in temperature caused by greenhouse gases to well below 2 degrees Celsius and to make efforts to limit global warming to 1.5 degrees Celsius.

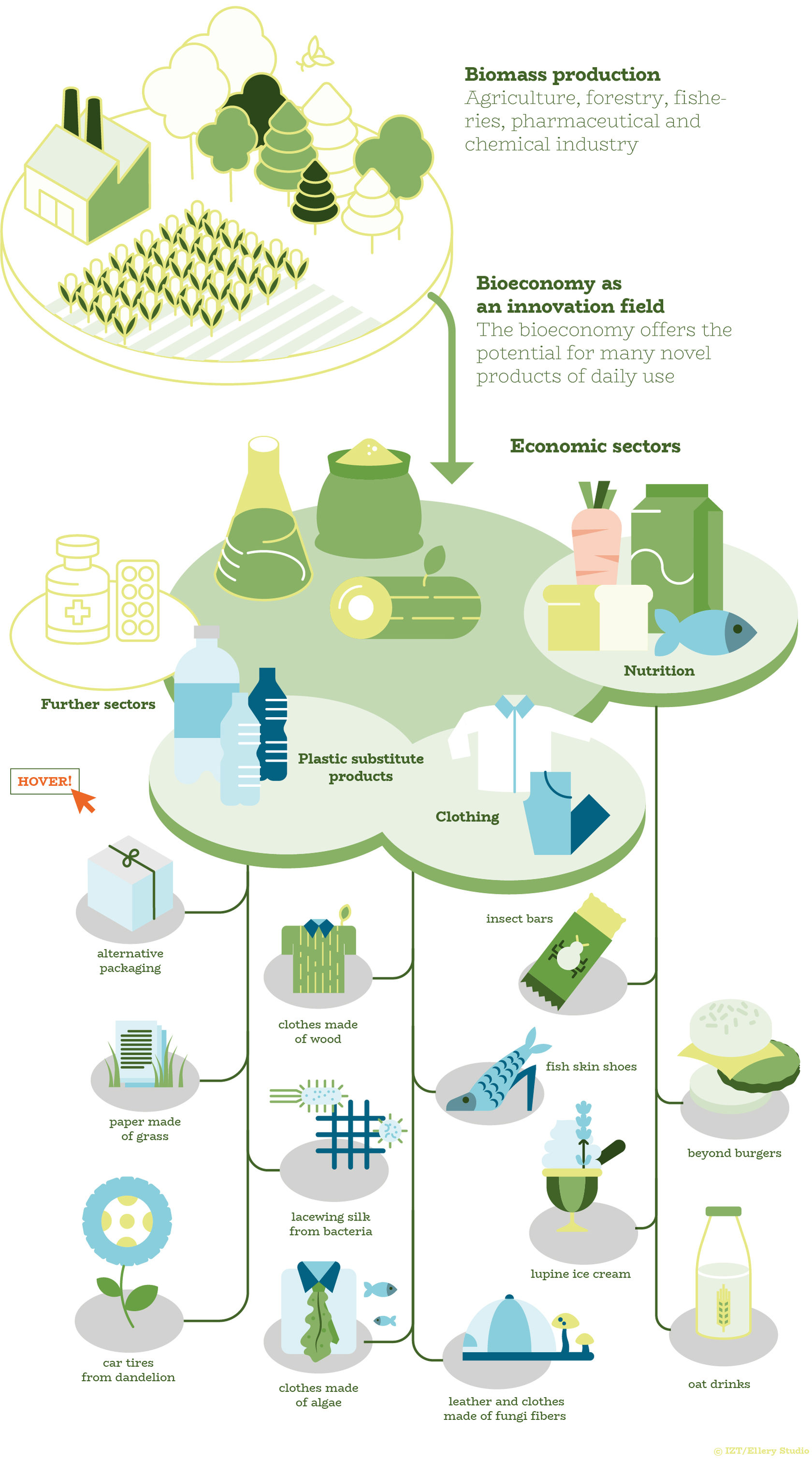

Bioeconomy – a brief explanation.

Bioeconomy refers to a form of biobased economic activity based on the production, development and use of biological resources (plants, animals and microorganisms) and oriented towards material cycles occurring in nature. In contrast to an economy based on fossil resources (oil, coal, natural gas), the bio-economy represents a development opportunity for a sustainable economy and lifestyle through the use of renewable resources and energy sources.

However, the development of the bioeconomy is controversially discussed with competing interests. The focus is mainly put on the development of biotechnologies in order to open up new markets and jobs. However, the bioeconomy comes with conflicting goals. These arise from the increased demands for biomass and the associated land use competition. It is therefore necessary to decide to what extent biomass should be used for the production of food, consumer goods or energy. Additionally, the growing demand for biomass and its increased production can intensify negative impacts on the environment and society - for example in the form of soil erosion, loss of biodiversity and land grabbing.

Conflicts of interest and objectives

A mere transition of the economy from fossil to bio-based would not go far enough. The transition to a more bio-based economy inevitably raises new questions of social and global justice. How can the food requirements of a growing world population be secured while at the same time reducing environmental damage? How can competing uses of land, soil and biomass be resolved in a fair way?

A new culture of the bioeconomy

Land Grabbing refers to the appropriation of land, especially agricultural land by investors and agricultural companies. By means of large-scale purchases or long-term leases, land is taken over in order to use it for the production of agricultural raw materials.

Definition based on:

German Bundestag and bpb/BICC

German Bundestag and bpb/BICC

The bioeconomy affects all areas of our lives and we encounter it everywhere. In recent years, the bioeconomy has gained momentum and significance worldwide. Numerous new bio-based products have already been established on the market or are under development. The spectrum ranges from plant-based burgers, insect bars and clothing made from algae, shoes made from fish skins to packaging made from bioplastics, car interiors made from liquid wood, terrace floorboards made from meadow grass and drinking straws made from fruit residues.

New biobased products gain importance

Move your cursor over the graphic and get more information.

Beyond-Burger

There are many vegetarian and vegan meat alternatives. Not all of them actually taste like meat or even similar to meat. Things are supposed to be different for the ‘Beyond Meat Burgers’, the third generation of ‘meat substitutes’. Taste, shape, color, texture and consistency are said to be similar to meat burgers. Commercial brand products of ‘Beyond Meat Burgers’ have only been available in Germany for a short time, but the demand is already huge. Their meat-like consistency and frying properties derive from a protein isolate of pea, soy or wheat. Beetroot juice is used, among other things, to imitate meat juice and keep the patty juicy. Other ingredients are vegetable oils, various flavors, stabilizers and antioxidants - the vegan patties still cannot do without additives.

There are many vegetarian and vegan meat alternatives. Not all of them actually taste like meat or even similar to meat. Things are supposed to be different for the ‘Beyond Meat Burgers’, the third generation of ‘meat substitutes’. Taste, shape, color, texture and consistency are said to be similar to meat burgers. Commercial brand products of ‘Beyond Meat Burgers’ have only been available in Germany for a short time, but the demand is already huge. Their meat-like consistency and frying properties derive from a protein isolate of pea, soy or wheat. Beetroot juice is used, among other things, to imitate meat juice and keep the patty juicy. Other ingredients are vegetable oils, various flavors, stabilizers and antioxidants - the vegan patties still cannot do without additives.

Lupine ice cream

One of the most distinctive protein plants in Germany is lupine, whose seeds have a protein content of 35%. With the blue sweet lupine Lupinus angustifolius, researchers found a variety that hardly contains any bitter substances (alkaloids), grows well in the local climate even in poor soils, is resistant to many diseases and has therefore become interesting for the food industry. As a nitrogen fixing plant, the lupine is a ‘soil improver’ and does not need to be fertilized. Meanwhile, various lupin-based foods are being developed. The first commercial product is an ice cream, which is available in supermarkets. It is interesting for vegetarians and vegans as well as for allergy sufferers.

One of the most distinctive protein plants in Germany is lupine, whose seeds have a protein content of 35%. With the blue sweet lupine Lupinus angustifolius, researchers found a variety that hardly contains any bitter substances (alkaloids), grows well in the local climate even in poor soils, is resistant to many diseases and has therefore become interesting for the food industry. As a nitrogen fixing plant, the lupine is a ‘soil improver’ and does not need to be fertilized. Meanwhile, various lupin-based foods are being developed. The first commercial product is an ice cream, which is available in supermarkets. It is interesting for vegetarians and vegans as well as for allergy sufferers.

Oat drinks

Lupines, soya, oats, almonds, rice and other seeds are now widely used to make drinks that can be used as an alternative to milk. The possible applications go beyond milk drinks (e.g. in coffee or muesli), more and more offer alternatives to classic dairy products such as yoghurt (e.g. made from oats, soya, coconut), cheese (e.g. made from lupins, almonds, cashews), crème fraîche (e.g. made from oats) etc. The increased demand for plant-based products leads to a growing number of attractive products, available to all consumers.

Lupines, soya, oats, almonds, rice and other seeds are now widely used to make drinks that can be used as an alternative to milk. The possible applications go beyond milk drinks (e.g. in coffee or muesli), more and more offer alternatives to classic dairy products such as yoghurt (e.g. made from oats, soya, coconut), cheese (e.g. made from lupins, almonds, cashews), crème fraîche (e.g. made from oats) etc. The increased demand for plant-based products leads to a growing number of attractive products, available to all consumers.

Insect bars

More than 2,100 different species of insects and spiders are currently consumed worldwide. Insects have a much smaller ecological footprint than cattle, pigs or chickens. Crickets for example, produce only 1% of CO₂ emissions per kilo of protein compared to beef. From an ecological point of view, a change in diet away from traditional meat to insects would be very desirable. However, both in terms of taste and ‘disgust’, there is considerable reluctance to eat insects, particularly in European cultures. Apart from curiosities, such as burgers, energy bars, insects ‘in one piece’ (alive or dried) to versatile insect flour, insects are primarily discussed at present as feed for classical meat and fish breeding (e.g. instead of imported soya). But insects could and will also be included in many other bioeconomy products in the future - for example, insect oil in cosmetics or fuels as well as chitin in plastic substitutes.

More than 2,100 different species of insects and spiders are currently consumed worldwide. Insects have a much smaller ecological footprint than cattle, pigs or chickens. Crickets for example, produce only 1% of CO₂ emissions per kilo of protein compared to beef. From an ecological point of view, a change in diet away from traditional meat to insects would be very desirable. However, both in terms of taste and ‘disgust’, there is considerable reluctance to eat insects, particularly in European cultures. Apart from curiosities, such as burgers, energy bars, insects ‘in one piece’ (alive or dried) to versatile insect flour, insects are primarily discussed at present as feed for classical meat and fish breeding (e.g. instead of imported soya). But insects could and will also be included in many other bioeconomy products in the future - for example, insect oil in cosmetics or fuels as well as chitin in plastic substitutes.

Wooden clothes

Surely our early ancestors used bark to protect themselves from wind and weather. But of course, you cannot imagine clothes made of wood like this anymore. Modern wooden clothing is neatly woven from wood fiber yarn. Wood-based fibers consume up to 20 times less water than conventional cotton fibers. In addition, unlike cotton plants, trees can do without pesticides and fertilizers. Since trees grow in our latitudes, transport distances could be minimized. Apart from the positive environmental aspects, wooden clothing is said to have properties which are very important for clothing: The fabric is permeable to air and balances temperature. The fabric quickly absorbs moisture and releases it directly back into the air. Thus, wooden shirts cool when warm, and warm when cold. Of course, wooden clothing can also be printed with a stylish bark pattern.

Surely our early ancestors used bark to protect themselves from wind and weather. But of course, you cannot imagine clothes made of wood like this anymore. Modern wooden clothing is neatly woven from wood fiber yarn. Wood-based fibers consume up to 20 times less water than conventional cotton fibers. In addition, unlike cotton plants, trees can do without pesticides and fertilizers. Since trees grow in our latitudes, transport distances could be minimized. Apart from the positive environmental aspects, wooden clothing is said to have properties which are very important for clothing: The fabric is permeable to air and balances temperature. The fabric quickly absorbs moisture and releases it directly back into the air. Thus, wooden shirts cool when warm, and warm when cold. Of course, wooden clothing can also be printed with a stylish bark pattern.

Leather and garments made of fungal fiber

There are almost countless different species of fungi with great properties. Yet their cultivation and economic potential has hardly been developed. Fungal fibers can be processed into clothing, for example. Among other species, the widely used tinder sponge, which Özi already knew, is used for this purpose. The fluffy, soft basic material is called Trama and was in the past a well-known textile material. Today, the craft of making clothes from Trama is almost extinct. It is possible, however, that fungi as textile raw materials is experiencing a new upswing due to the rising veganism. Vegan leather substitute products can also be produced from the mycelium of forest mushrooms, i.e. from their root network. These are fed with waste from agriculture and manufactured into products such as furniture, shoes and all kinds of other leather products.

There are almost countless different species of fungi with great properties. Yet their cultivation and economic potential has hardly been developed. Fungal fibers can be processed into clothing, for example. Among other species, the widely used tinder sponge, which Özi already knew, is used for this purpose. The fluffy, soft basic material is called Trama and was in the past a well-known textile material. Today, the craft of making clothes from Trama is almost extinct. It is possible, however, that fungi as textile raw materials is experiencing a new upswing due to the rising veganism. Vegan leather substitute products can also be produced from the mycelium of forest mushrooms, i.e. from their root network. These are fed with waste from agriculture and manufactured into products such as furniture, shoes and all kinds of other leather products.

Shoes made of fish skin

Fish skins are a waste product of aquaculture and fisheries that are usually disposed of. However, they can actually be tanned and processed into attractive leather. A shoe with a sturgeon pattern or a jacket made of iridescent salmon leather are quite chic yet do not become slimy in humid weather. Several - mainly small businesses - have specialized in fish leather and serve a high-priced market with unusual shoes and other leather products.

Fish skins are a waste product of aquaculture and fisheries that are usually disposed of. However, they can actually be tanned and processed into attractive leather. A shoe with a sturgeon pattern or a jacket made of iridescent salmon leather are quite chic yet do not become slimy in humid weather. Several - mainly small businesses - have specialized in fish leather and serve a high-priced market with unusual shoes and other leather products.

Clothes from algae

Many of our waters are over-fertilized and various algae feel very comfortable in them. These algae can be harvested with a clear conscience to make clothing from their fibers. Algae clothing is now offered by numerous manufacturers. Currently, algae only provide a part of the fibers, but nevertheless, often almost 50% of the product consists of algae fibers. Most of the fibers are made from seaweed. They do not at all smell fishy and do not fall apart when it rains. The active ingredients contained in the algae are also said to promote cell regeneration and to reduce itching and skin diseases (such as neurodermatitis). Should the advertised properties of the ‘healthiest shirt in the world’ prove to be true, algae fibers certainly have a great future ahead of them.

Many of our waters are over-fertilized and various algae feel very comfortable in them. These algae can be harvested with a clear conscience to make clothing from their fibers. Algae clothing is now offered by numerous manufacturers. Currently, algae only provide a part of the fibers, but nevertheless, often almost 50% of the product consists of algae fibers. Most of the fibers are made from seaweed. They do not at all smell fishy and do not fall apart when it rains. The active ingredients contained in the algae are also said to promote cell regeneration and to reduce itching and skin diseases (such as neurodermatitis). Should the advertised properties of the ‘healthiest shirt in the world’ prove to be true, algae fibers certainly have a great future ahead of them.

Bacterial lacewing silk

Green lacewings are small green flies with golden eyes that eat aphids. They attach their eggs on extremely flexible stalks up to 10 mm long - made of a hardened protein excretion - on the surface of the leaves. These egg stems, or better said, this lacewing silk, is extremely flexible and stable. The mechanical properties of the egg stems were biotechnologically reproduced as a fiber. Using bacteria, the lacewing silk can now also be produced on a large scale and is used in medical technology and as a reinforcing fiber for lightweight construction, for example in the production of cars, airplanes, or ships.

Green lacewings are small green flies with golden eyes that eat aphids. They attach their eggs on extremely flexible stalks up to 10 mm long - made of a hardened protein excretion - on the surface of the leaves. These egg stems, or better said, this lacewing silk, is extremely flexible and stable. The mechanical properties of the egg stems were biotechnologically reproduced as a fiber. Using bacteria, the lacewing silk can now also be produced on a large scale and is used in medical technology and as a reinforcing fiber for lightweight construction, for example in the production of cars, airplanes, or ships.

Packaging material

The fact that packaging material is still made of plastic must come as a surprise, ecause there already are countless alternatives today. Fiber-cast packaging, for example: material containing fibers is ‘cast’ into a precisely fitting packaging according to the shape of the article to be packaged, which optimally protects the product and saves material at the same time. Fiber-cast packaging can be pressed directly from agricultural waste that is not used for other purposes. Optionally, mushrooms can be grown on this waste to improve and stabilize the shape of the packaging. At the end of the day, these bio-economic packaging materials can be easily composted.

The fact that packaging material is still made of plastic must come as a surprise, ecause there already are countless alternatives today. Fiber-cast packaging, for example: material containing fibers is ‘cast’ into a precisely fitting packaging according to the shape of the article to be packaged, which optimally protects the product and saves material at the same time. Fiber-cast packaging can be pressed directly from agricultural waste that is not used for other purposes. Optionally, mushrooms can be grown on this waste to improve and stabilize the shape of the packaging. At the end of the day, these bio-economic packaging materials can be easily composted.

Paper from grass

The first paper was made from papyrus – a grass that grows in swamps. Since then, the demand for paper has increased tremendously. Nowadays it is mainly produced from wood. But paper can (once again) be made from grass – from grass that can be mowed from meadows several times a year. Grass paper is particularly suitable for packaging materials and cardboard. But it can also be used for digital and offset printing, for brochures, labels, booklets, and business cards.

The first paper was made from papyrus – a grass that grows in swamps. Since then, the demand for paper has increased tremendously. Nowadays it is mainly produced from wood. But paper can (once again) be made from grass – from grass that can be mowed from meadows several times a year. Grass paper is particularly suitable for packaging materials and cardboard. But it can also be used for digital and offset printing, for brochures, labels, booklets, and business cards.

Dandelion tires

Car tires used to be made exclusively from rubber – the sap of the hevea tree, which is still widely cultivated in the tropics today. Other plants that produce sticky sap, such as the dandelion, are also suitable. The company Continental has presented a first test tire, which is partly made of rubber and partly of dandelion. A particularly high-yielding and robust variant of the Russian dandelion was specially bred for this purpose. The long-term goal is to find an ecologically, economically, and socially sensible solution to the growing demand for natural rubber that will relieve the growing areas for the traditional rubber tree in the tropics. The rubber dandelion can be cultivated on previously unused land in the temperate latitudes of Europe - and thus in geographical proximity to the European tire plants. This significantly reduces logistics costs and environmental pollution.

Car tires used to be made exclusively from rubber – the sap of the hevea tree, which is still widely cultivated in the tropics today. Other plants that produce sticky sap, such as the dandelion, are also suitable. The company Continental has presented a first test tire, which is partly made of rubber and partly of dandelion. A particularly high-yielding and robust variant of the Russian dandelion was specially bred for this purpose. The long-term goal is to find an ecologically, economically, and socially sensible solution to the growing demand for natural rubber that will relieve the growing areas for the traditional rubber tree in the tropics. The rubber dandelion can be cultivated on previously unused land in the temperate latitudes of Europe - and thus in geographical proximity to the European tire plants. This significantly reduces logistics costs and environmental pollution.

Plastics are omnipresent in our living environment, and many of them can be made from bioeconomically produced raw materials. These can be synthetic fibres, but also classic plastic items such as cutlery, plates, paper and much more. There is still a lot of development potential here. Material saving, monomaterial and recyclability are the keywords of the future. Monomaterial packaging is the term used to describe packaging that consists of only one type of material, in order to improve the sorting of waste and thus its recyclability.

Leather and clothes made from mushroom fibers or fish skins, clothes made from scraps of wood or algae are already a reality today. Fibers suitable for producing clothing can be developed from an incredible variety of bioeconomic raw materials, ranging from sheep to bacteria. Today, a market for these alternative products has developed especially in the fashion sector. Some are ready for the market, and many of them are now considered fashionable and chic.

There are major challenges in the food sector, but also many innovative ideas and products. For instance, products that we often come across when shopping are the Beyond Burger, lupine ice cream, oat milk and insect bars. Generally, regional foods require less transportation and therefore less fuel. Vegan food produces less greenhouse gases, uses less land and conserves groundwater. Last but not least, food packaging also requires plastic alternatives, resource efficiency and recyclability. The fewer animal products, the fewer livestock; the more regional and less packaged, the more ecological and bioeconomical.

Economic raw material utilization has changed in the course of human history. Until the Middle Ages, renewable biomass was the most important source of raw materials and even then, especially the European forests were massively over-exploited and mostly destroyed. This destruction reached its peak in the 18th century with the shortage of wood due to the large-scale deforestation for shipbuilding, urban construction and manufacturing.

Biomass as a source of raw materials

The short-age of fossil fuels

The Industrial Revolution

The shortage of wood gave an important impulse for the development of coal and oil as new sources of energy and thus also triggered the Industrial Revolution. Today mankind is facing a new epochal turning point. The use of coal, oil and natural gas is massively changing the climate and thus endangering the prosperity we have achieved so far. The economy and consumption must therefore switch to regenerative, biobased raw materials - and doing so in a sustainable manner.

But the challenges will be greater than in past centuries. The global economy has meanwhile increased its production, material and energy consumption more than tenfold, and around 8 billion people want to live in prosperity. A large part of the net primary production of land areas, e.g. the (annual) increase in plant biomass, is now already appropriated by humans. Our status quo will not be maintained simply by returning to concepts from before the 18th century. The bioeconomy of the future therefore is yet to be developed.

New challenges

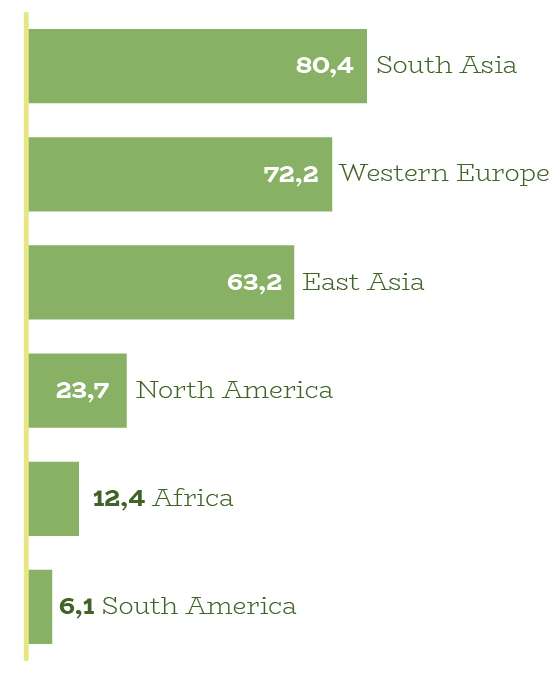

Appropriation of net primary production by region (in percent)

Bioeconomy can make a decisive contribution to solving world challenges. However, increased use of biomass alone does not lead to greater sustainability! It all depends all on the type of biomass extraction, production and use. Let's look at two examples: biofuels and bioplastics.

Biofuels

Biofuels are fuels produced from biomass. Materials used include renewable raw materials such as oil plants, crop, sugar beet or cane, forest and residual wood or wood from fast-growing plantations. Just because they are produced from biomass does not necessarily make biofuels more environmentally friendly than fossil fuels. It is true that some biofuels emit more than a third less greenhouse gases than petrol or diesel. However, if forests and bushes are cleared to grow energy crops, the greenhouse gas balance deteriorates considerably. The cultivation and processing of the raw materials (such as corn or soya) also causes other environmental impacts that significantly worsen the overall ecological balance. Therefore, not all biofuels are the same! It also shows that the amount of domestic bioenergy is limited. Residual materials have potential – especially ethanol from lignocellulose and synthetic biofuels, also known as BtL (biomass to liquid) fuels, could make a significant contribution to this.

Environmental impact and greenhouse gas emissions of biofuels.

The effects of biofuels differ according to raw materials and usage contexts (or region).

Bioplastics

Bioplastics produced from renewable resources such as plant materials, microorganisms, insects or fungi can be an alternative to conventional plastics, in which its raw material is fossil oil. However, the life cycle assessment is not necessarily better if raw materials are biobased instead of fossil-based. The effects tend to shift: While fossil-based plastics release more climate-impacting CO₂, the ecological footprint of biobased plastics shows a higher acidification and eutrophication potential. This is due to the agricultural production of the raw materials. There are also problems with recycling; sorting systems are not yet designed to separate these plastics. Bioplastics therefore usually end up in energy recovery. According to the German Environment Agency, the disposal of biodegradable plastics through biowaste collection also does not make ecological sense, and does not represent high-quality recycling. The currently available biodegradable plastics cannot solve the problem of ‘littering’. The decisive measure still remains to be avoiding plastic waste entering into the environment through its collection and recycling. Conclusion: biobased plastics are far from being more environmentally friendly than conventional plastics. Without the establishment of a circular bioplastics economy, bioplastics are not yet a solution for the handling of plastics.

Not all bioplastics are the same

The classification of bioplastics in the ‘biopolymer cross’ of the IfBB shows that bioplastics differ according to their raw materials and degradability.

Biodiversity as a resource and

source of knowledge

source of knowledge

The number of different animals, fungi, plants and microorganisms living on our planet is difficult to estimate. About 1.9 million species have been scientifically described so far. However, thousands of new species are constantly being discovered and it is estimated that 80-90% of the species have not yet been registered. All these species, their genetic diversity and the diversity of ecosystems are summarized as biodiversity. However, the extent of how diverse the biodiversity actually is, is hardly documented. Of the 1.9 million species described, we usually do not know much more than the fact that they exist. How they live and communicate, what they eat, what conditions they depend on, and how they structure and shape their ecosystems – this is known for only a few hundred species.

We are very attached to a few proven microorganisms, fungi, plants and animals. Basic research is expensive and time-consuming, and we know much more about pigs and rye than about muntjaks and the grass dasypyrum. Each of the millions of species is unique in terms of its properties, physiology, the chemical building blocks it produces and the behavior it develops to deal with the challenges of everyday life. Many of these properties may be essential for us humans in our way towards a sustainable, bioeconomic society in the future.

No bioeconomy without biodiversity

For this reason, the Museum für Naturkunde Berlin is also researching biodiversity from the perspective of bioeconomy. Millions of objects are stored here - mechanical structures, surfaces, chemicals and much more can be discovered in numerous versions and variations. There are often hundreds of small and large variations – for example in their ‘bionic solutions’. Which of these is the best must first be examined. The Museum für Naturkunde Berlin is currently working on making the millions of objects in the collection available to users digitally.

The museum as a place of

biodiversity research

biodiversity research

The living museum

The Museum für Naturkunde Berlin is a place of biodiversity research.

A Look Inside the Museum

Change towards a biobased economy is developing very dynamically worldwide. It is largely driven by scientific and technological innovations. However, the dynamics of innovation is also dependent on numerous social processes and interaction between society, technology, economy and the environment. These include, in particular, competition for scarce land and resources, land-use conflicts, changes in agricultural and forestry practices, and changing lifestyles and consumer preferences. In this interplay between various factors, three development paths emerge: the efficiency path, the consistency path and the sufficiency path.

Peepholes into the future

Peepholes of the bioeconomy

Three development paths can be combined for the possible future in bioeconomy.

The efficiency path is the one that is most compatible with the prevailing economic situation, but it only serves as a basic strategy. Efficiency gains alone will not suffice to compensate for the harmful side effects of the global increase in food and biomass demand - nor will they be sufficient to meet climate protection and environmental requirements. The consistency and sufficiency paths are more far-reaching, and they have the greatest potential for a transformation towards a sustainable bioeconomy. The development of the bioeconomy therefore depends on a smart combination of all three paths, which requires exploring the possible, alternative and linkable future paths. This also means that bioeconomy is everyone's business!

Combinations of futures

Further bioeconomic futures can be experienced in the special series ‘Visions of the Bioeconomy’ (11.-17.09.2020) of the International Literature Festival Berlin - one of the partner projects within the Wissenschaftsjahr 2020|21 (Science Year 2020|21)!

The question is: how can we shape a bioeconomic future in a way that enables global prosperity and social justice, while staying within the planetary boundaries? Replacing fossil fuels with biobased raw materials is only a step towards a sustainable economy. The development of the bioeconomy will only become sustainable if the limited availability and regenerative capacity of biomass is taken into account. This must be produced and efficiently used under ecological and ethical requirements.

Development of a sustainable bioeconomy

Innovation and phasing out of socially and ecologically harmful practices

An innovation policy that focuses primarily on new technologies, processes and products for the use of biogenic raw materials, and on knowledge of biological processes and systems for new applications will not be sufficient. Rather, innovation must be accompanied by exnovation, i.e. not the introduction of new ideas, production processes, lifestyles and cultural practices, but the abandonment of existing ones. For example, coal-fired power generation is not compatible with climate protection, hence coal phase-out is the logical thing to do. Similarly, we should phase out of environmentally harmful practices in agriculture, forestry and fisheries, and abandon unsustainable consumption and eating habits.

The SDGs: Compass for a sustainable bioeconomy

The compass for the development of a sustainable bioeconomy is provided by the United Nations' Agenda 2030 for Sustainable Development. The aim of the Agenda is a worldwide transformation - a comprehensive change - towards a sustainable economy and way of life. A bioeconomy that simultaneously satisfies human needs and preserves the environment is of central importance for the implementation of the Sustainable Development Goals (SDGs).

The team behind [bio’nd]

The organizers and executers are the IZT – Institute for Future Studies and Technology Assessment, the Museum für Naturkunde Berlin and Ellery Studio, jointly developing this series of events. This project is funded by the Federal Ministry of Education and Research within the 'Year of Science 2020/21- Bioeconomy'.

Contact

IZT

Institute for Futures Studies and Technology Assessment

Institute for Futures Studies and Technology Assessment

Dr. Siegfried Behrendt

s.behrendt@izt.de

(Content, concept, and coordination)

With the cooperation of:

Jakob Zwiers (project coordination)

Ralph Eyrich

Website IZT

Museum für Naturkunde Berlin

Area: Bioeconomy and Biodiversity

Area: Bioeconomy and Biodiversity

Dr. Jörg Freyhof

joerg.freyhof@mfn.berlin

(Advice on content)

With the cooperation of:

Martina Lutz

Website Museum für Naturkunde Berlin

Museum für Naturkunde Berlin

Experimental Field for Participation and Open Science

Experimental Field for Participation and Open Science

Dr. Wiebke Rössig

wiebke.roessig@mfn.berlin

(Development and implementation of events)

With the cooperation of:

Bonnie Dietermann

(project coordination)

Website Museum für Naturkunde Berlin – Experimentierfeld

Ellery Studio

Studio for Creative Strategy

Studio for Creative Strategy

Dodo Vögler

dodo@ellerystudio.com

(Concept, editing and creation of the website and the installation)

With the cooperation of:

Julia Zimmermann

David Ramirez Fernandez

Sheree Domingo

Gaja Vičič

Eugen Litwinow

Bernd Riedel

Website Ellery Studio